|

case study | automotive |

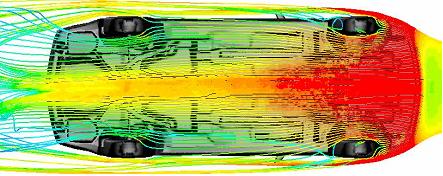

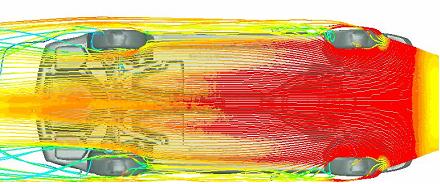

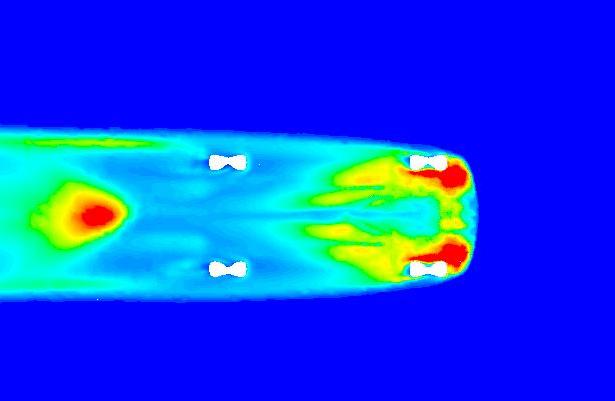

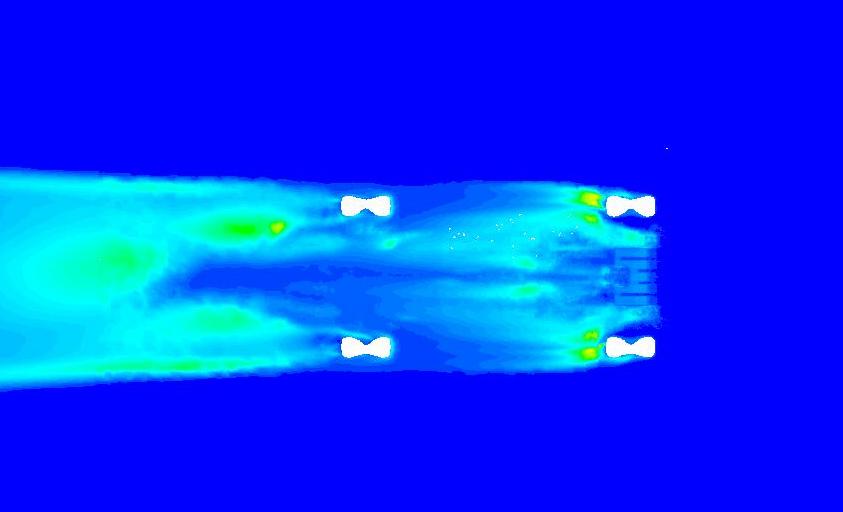

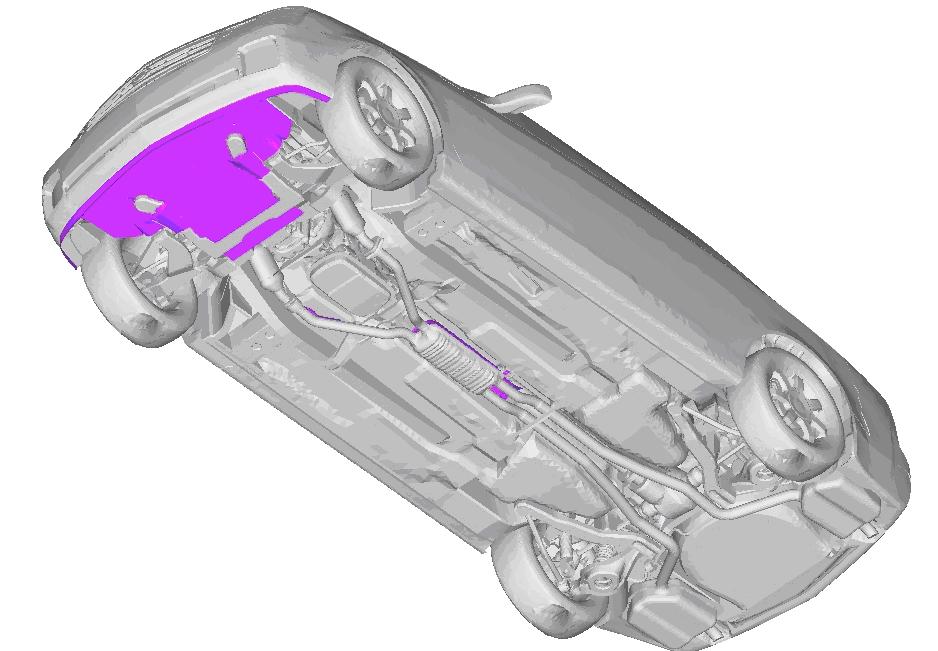

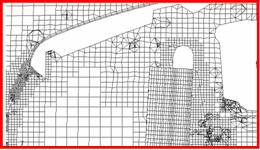

Harpoon speeds up CFD analysis at Rieter Automotive Designing the modern day car has become an extremely complex problem. Not only must the car be pleasing to the eye, but it must be comfortable, reasonably priced and fuel efficient as well. Based in Winterthur, Switzerland, Rieter Automotive Systems is one of the leading global suppliers of systems solutions in the field of noise control and thermal management for the automotive industry. Rieter Automotive Systems offers innovative solutions within a Total Vehicle Approach to make cars more comfortable, lighter and more efficient. To achieve their goals, Rieter uses CFD, together with radiation analysis, to support its business units in thermal shielding, engine undertrays and underbody covers. Rieter also offers research in new thermal/aerodynamic packaging concepts for the whole vehicle focusing on better control (mixing or splitting) of hot and cold airflows. To do this, detailed underhood and underbody vehicle models are required. With the help of Harpoon, the extreme mesher developed by Manchester, UK-based Sharc, Rieter has been able to make complex full car model creation a much more simple task than with previous methods. Harpoon is a fully automatic hex dominant mesher, which can mesh complex geometries directly from the raw CAD without the need for a surface mesh. These unique features combined with an industry aware, enthusiastic development schedule have led to Harpoon being a revolutionary tool within the automotive sector. “Meshing is a critical part of this process” says Edward Bendell, Thermal CAE Specialist. “Fitting a good-quality mesh between closely spaced components is very challenging, and in the past we could not trust 3D volume meshing software to give a mesh within a certain time deadline, therefore leading to uncertainty in managing analysis projects. With Harpoon, this problem has all but been eliminated.” “The biggest advantage of Harpoon is that, whilst mesh problems can still occur, they can be quickly identified and rectified, in a ‘human time scale’”, adds Bendell. “Usually it takes several re-meshes before the analyst is happy, but at 5-10 minutes per mesh, this is no longer the bottleneck it once was, freeing up the engineer to fine-tune to get the best mesh possible rather than being happy to have a valid mesh at all.“ “Because the resulting meshes are strongly hex-dominant, the ratio of solution quality to mesh size is far better than would be expected on a mesh which includes Tetrahedra”, explains Bendell. “Our correlation research based on wind tunnel experiments has also shown cell type to be important for obtaining good thermal solutions when convection is a part of the process.” Rieter uses Harpoon to create detailed meshes including boundary layers (important for heat protection work) on the full car. Typical meshes consist of 7.5 million cells with a cell resolution of 20mm in the wake area. This leads to a good aerodynamic solution. Drag Reduction One of the most important areas of work is drag reduction. Rieter uses Harpoon to help with this. A production car with two different underfloors (see images above), were compared. A drag reduction of 10% (Cd 0.33 to 0.30) was discovered using Harpoon with a new, flatter underbody concept. “Harpoon is a very useful tool for performing multiple-case studies, because it is easy to modify the geometry and then re-mesh everything automatically in 5 minutes”, Bendell. Underbody Streamlines for Cd = 0.33 (floor 1) Underbody Streamlines for Cd = 0.30 (floor 2) Underbody turbulent kinetic energy for Cd = 0.33 (floor 1) Underbody turbulent kinetic energy for Cd = 0.30 (floor 2)

|

Underfloor 1 Cd = 0.33 Underfloor 2 Cd = 0.30

Close up of BL

|