|

case study | automotive |

Case Study by DaimlerChrysler Internal Flow through a Water Pump The purpose of a recent study performed by DaimlerChrysler was to compare the performance of Harpoon-based CFD against previous solutions using tetrahedral meshes. The effect of mesh skew on accuracy and convergence was observed. 14 operating cases were simulated: 1000-7500rpm at 500rpm increments. Inlet velocities were derived based on the test mass flow measurements. Pressure rise & flow split between volutes were solved. Excellent agreement was obtained using a Harpoon mesh, containing approximately 3M cells, at a fraction of the simulation effort required for a full tet mesh. The following was concluded from this effort:

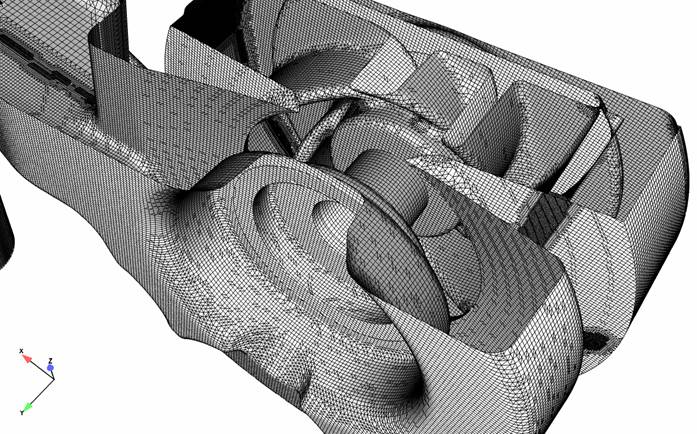

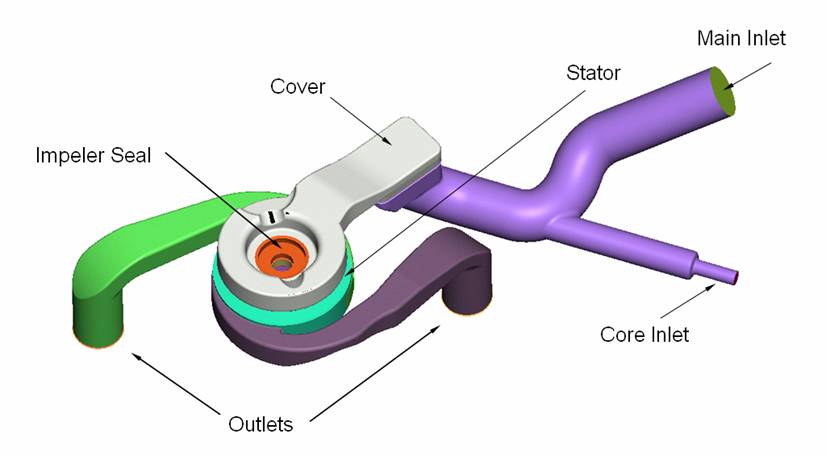

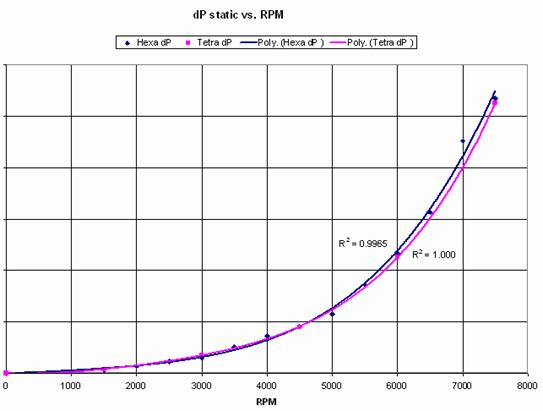

Details of the model are shown in figure 1. A close-up of mesh details is shown in figure 2. Figures 3 and 4 compare results for Harpoon meshes (blue) against tet mesh results (magenta). (all data courtesy DaimlerChrysler)

|

Figure 1 shows the model

Figure 3 shows Pressure v RPM

Figure 4 shows Efficiency v RPM |