Modeling hazardous scenarios has become an essential part of engineering design for Offshore activities. Physical testing can be prohibitively expensive and in some cases impossible so modern Computational Fluid Dynamics (CFD) techniques are commonly used for the modeling of exhaust plume dispersion, natural and forced ventilation efficiency, flaring, toxic gas releases, fires, explosions and hazardous spills.

Conducting and interpreting simulation research requires a substantial amount of specialist knowledge and so Offshore organisations frequently outsource the task to dedicated companies. One such company is Abbott Risk Consulting (ARC) Ltd, an independent consultancy, that provides services to the defence, transportation, marine and energy sectors. The services include safety, risk, reliability and environmental engineering assessments.

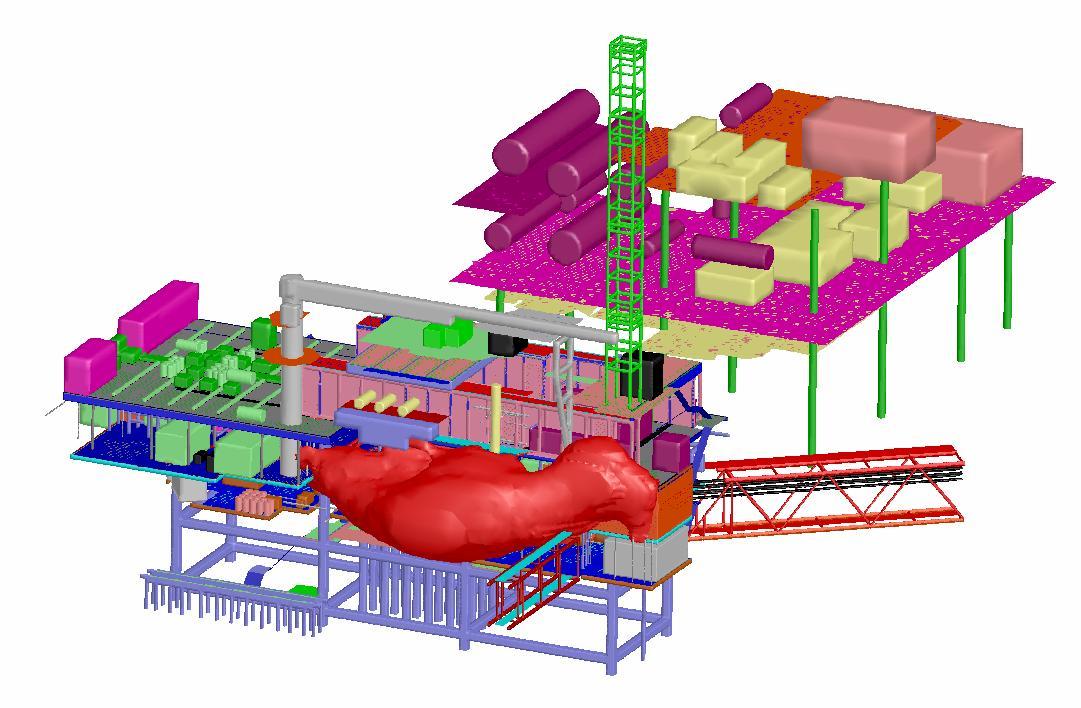

A major oil company approached ARC to conduct a Fire & Explosion Risk Assessment (FERA) on a new offshore platform design. As part of this assessment, it was required to determine the magnitude and location of overpressures on a critical blastwall following a flammable gas release and explosion.

The modeling of all the detail present within the process area of the platform, such as pipework and cable trays, presented a significant challenge to ARC's existing meshing process.

Traditionally, an estimate of blockage within these areas was made and a porosity model implemented, as opposed to meshing the detail explicitly. However, due to the varying congestion within the immediate vicinity of the leak locations, ARC was concerned that the use of a porosity model could lead to significant errors being introduced to the dispersion model and carried forward to the explosion model.

"The use of Harpoon allowed the meshing of small detail which significantly increased our and our client's confidence in the results," says Simon Feven, CFD engineer

ARC was provided with various 2D drawings and PDMS CAD data from which the model was to be constructed. After conversion and simplification in a third party CAD package, the model was exported in STL format ready for import to Harpoon.

"The meshing technique used by Harpoon greatly reduced the time needed to manually process the model in CAD before meshing," comments Feven. " For example, the intersection of equipment with the deck was handled gracefully and didn't require a split or union operation to ensure a good quality mesh at the join."

An additional advantage was that the geometry model could be updated as required by the client and re-meshed in a fraction of the time it would have taken with ARC's other mesh tools.

"The study required many gas leak sizes and locations to be modeled. Each of these leak scenarios required unique meshes which can lead to a high run cost " adds Feven. " Using Harpoon allowed us to remain competitive, even compared to competitors that proposed simpler and more approximate modeling techniques, by automating the majority of the meshing process."

"Harpoon's batch capability ensured that once the first mesh was created, the generation of the remaining meshes was trivial, " Feven continues. "Once each mesh was created, Harpoon's GUI allowed effective review of the produced mesh and evaluation of the mesh quality."

The key benefit that Harpoon offered was the hex-dominant meshing algorithm. This allowed fast refinement of the mesh to the fine level required to resolve the detail in the process area. The use of mainly hexahedral cells meant that fewer cells were needed to correctly resolve the dispersion of the cloud compared to the traditional method of using tetrahedral cells. Hence, modeling the increased detail was possible without significantly increasing the computational cost of the study.

When the meshes were completed, they were exported to the FLUENT solver and transient dispersion runs executed. An example of the maximum flammable envelope resulting for one of the large leak scenarios is shown above.

Various gas cloud dispersion scenarios were modeled within the hazardous areas by CFD. User-defined functions were written by ARC to transfer the resulting flammable clouds into the explosion solver, AutoReaGas (ARG). Several explosions with varying ignition point locations were simulated to produce a full range of realistic scenarios.

The resulting overpressures were correlated with a leak and ignition frequency model to allow structural engineers to design the blastwall to withstand any likely explosions over the life of the platform.

Continued application of Harpoon to other projects has enabled ARC to significantly reduce the time required to construct a mesh from CAD data whilst increasing model quality.

Gas Cloud formation around Rig

Section through Process area mesh